The potential and challenges of carbon nanotubes (CNT)

Carbon nanotubes (CNT) are cylindrical structures with diameters in the nanometer range, composed solely of carbon (1). CNTs are extremely stable materials. Despite being about half as dense as aluminum and very light, they are about 20 times stronger than steel. They also have high current density tolerance (more than 1000 times that of copper) and higher thermal conductivity than copper. Additionally, due to their fine structure, they have a very large surface area, which is also a useful property.

Due to these characteristics, CNTs are deeply involved in modern technologies such as energy storage materials, sensors, nanocomposites, and water purification. On the other hand, high-energy or chemical processes are required to produce CNTs, raising concerns about their impact on the environment and human health. To address these issues, research is underway to synthesize CNTs from natural components.

References: https://www.nature.com/articles/s41598-024-65893-6

Making CNTs from corn

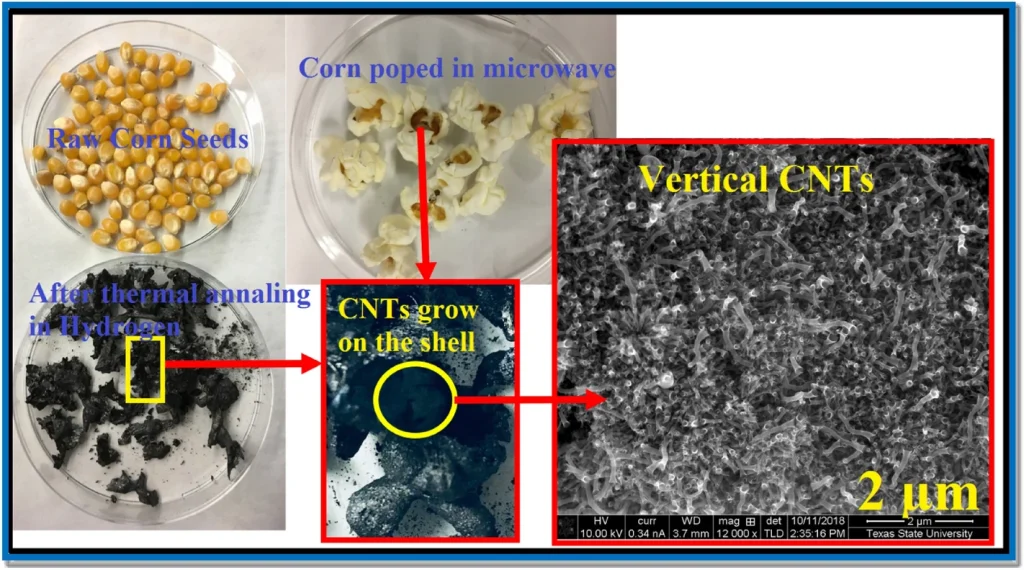

In the study introduced here, corn seeds, which are the material for popcorn, were used. Corn seeds were chosen because of their high carbon content and because carbon atoms organize to produce amylose and amylopectin. When this material is heat-treated in a reducing medium, the removal of oxygen-containing groups is promoted, forming graphite nanostructures. In this study, heating in hydrogen gas at high temperatures (800, 900, 1050°C) caused the corn to become popcorn-like, and further heating synthesized CNTs on the surface. This method, using natural corn seeds and no harmful substances as catalysts, is a safe method with low environmental and human impact. Interestingly, the shape and properties of CNTs changed depending on the heating temperature. This suggests the possibility of selectively producing different types of CNTs.

Characteristics of corn-derived CNTs

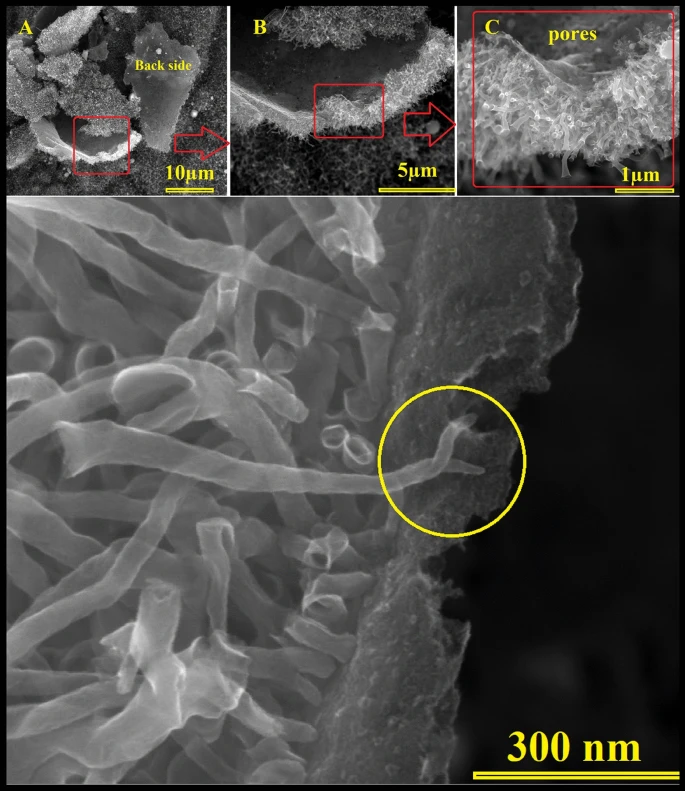

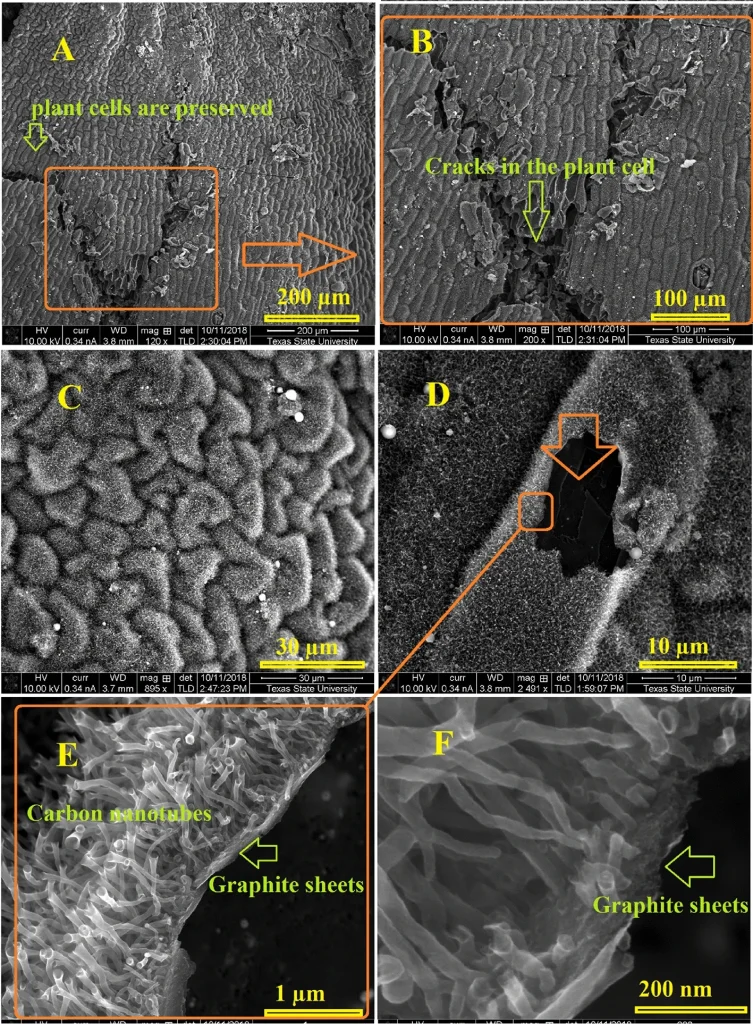

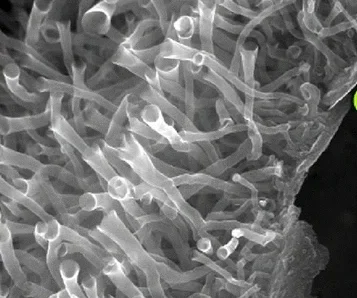

CNTs form on the surface of corn. High-temperature treatment generates volatile gases within the structure, which are self-extruded through pores, causing trumpet-shaped carbon nanotubes to grow. The cylindrical structure greatly increases the surface area, with CNTs produced at 1050°C having an enormous surface area of 710 square meters per gram. The shape of CNTs formed varies with the processing temperature. For example, heating at 900°C results in a structure where many small tubes emerge from larger tubes, while heating at 800°C produces cage-like structures made of CNTs. These structures have different properties and application fields, making the technology to produce the optimal CNT for each use groundbreaking.

Will natural-derived CNTs become common?

Research on CNTs is advancing rapidly, with new applications being explored. They are already used in fields such as water purification and energy storage, leveraging their large surface area and adsorption capacity. Additionally, CNTs are being studied for use in plant genetic transformation (2), with applications being developed daily. However, synthesizing CNTs requires high energy, and there are concerns about their impact on human health during synthesis. The method introduced here, using natural materials without chemicals, may become the standard for CNT synthesis in the future. CNTs, too small to be familiar, may feel more approachable when thought of as relatives of popcorn. The future development of this field is exciting.

(1) https://unit.aist.go.jp/ncdrc/ja/news/CNT in brief.pdf

(2) https://www.nature.com/articles/s41467-022-30185-y

コメント